Robots can play an important role in manufacturing companies and can yield numerous advantages. Here are some of the ways in which robots can help manufacturing companies:

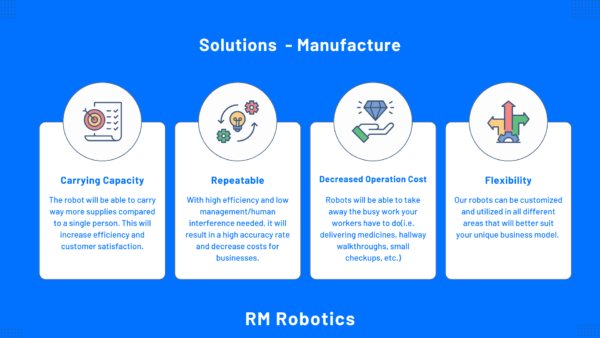

1. Increased productivity is a considerable benefit. Robots are not limited to the human needs like sleep, eating, etc. and therefore can be way more productive than humans are at repetitive mundane tasks. They not only can perform these tasks but they can do it with high precision and speed, in turn they can help humans focus on more intricate tasks or on connecting with customers.

2. Improved quality control is another big focus on what these Robots can help with in daily work-life. They can perform quality checks during the manufacturing process and make sure that quality is consistent and accurate. They can be trained to detect defects or deviations, which is very important in making sure that all products are of a high quality value.

3. Improved safety is a huge factor in the role that robots can play in manufacturing companies. One of the main reasons human employees end up having to miss or change positions is because of the physical demand and dangerous environments that they have to work in. By embracing robots in the workfield, these employees can focus on the less dangerous tasks while the robots can handle working with toxic substances, heavy lifting, and other duties that would be an injury risk for humans.

4. Increased efficiency is one way that the manufacturing industry can improve with robots. Robots can accelerate the speed in which several manufacturing processes are done, including assembly, packaging, and material handling to name a few. They can also decrease waste, enhance energy efficiency, and lesson errors that humans would otherwise make. All in all, this can help improve operational efficiency and let employees focus on more important tasks.

5. Cost savings are another way that robots can enhance manufacturing work-life. The initial investment in robotics technology can be substantial, the return of investment can lead to long-term savings for the company over time. They can reduce costs that can usually stem from human error, which can result in the company being more productive for less of the cost.

6. Flexibility and adaptability are certainly big factors in the manufacturing industry and those can also be mended and improved by robots. Since robots can be programmed and reprogrammed to carry out various duties, they can easily be altered to handle different products. They can even be reconfigured to adjust with changes in production requirements, which is important for an ever evolving market like manufacturing can be.

7. Data collection and analysis can be evolved through the use of robots as well. Robots can be fitted with sensors and advanced technology can collect data during the process of performing tasks. This data can be examined to detect patterns, identify production limits, and to make informed decisions for overall improvements and forecasting future maintenance.

8. Collaborative work environments can be encouraged, especially with cobots, which are collaborative robots that are designed to work alongside human employees. They can support humans with tasks that demand for human decision making, which can overall make tasks go more smoothly as well as improving human-robot collaboration resulting in a more coefficient work environment.

9. Scalability is often an undiscussed factor in the call for robots in the manufacturing industry. Scalability is important because depending on the needs of the establishment, robots can be scaled up or down. Demand can be fluctuating and for that reason, it is very convenient to adjust the number of robots that are deployed at any given time, which can allow for great flexibility without any large foundational changes.

In conclusion, the pros outweigh the cons when it comes to embracing robots in the manufacturing industry. The increased productivity, improved quality control, enhanced safety, cost savings, and all of the reasons above are just some of the few benefits that robots will bring to the workforce. The innovative companies that are the first to venture into having robots in the workplace will also be the first companies to profit on the numerous advantages that this technology can bring. Visit us at.

Interested in learning more? Get in touch and book a discovery call HERE.